INDIGO DYEING : Questions & Answers

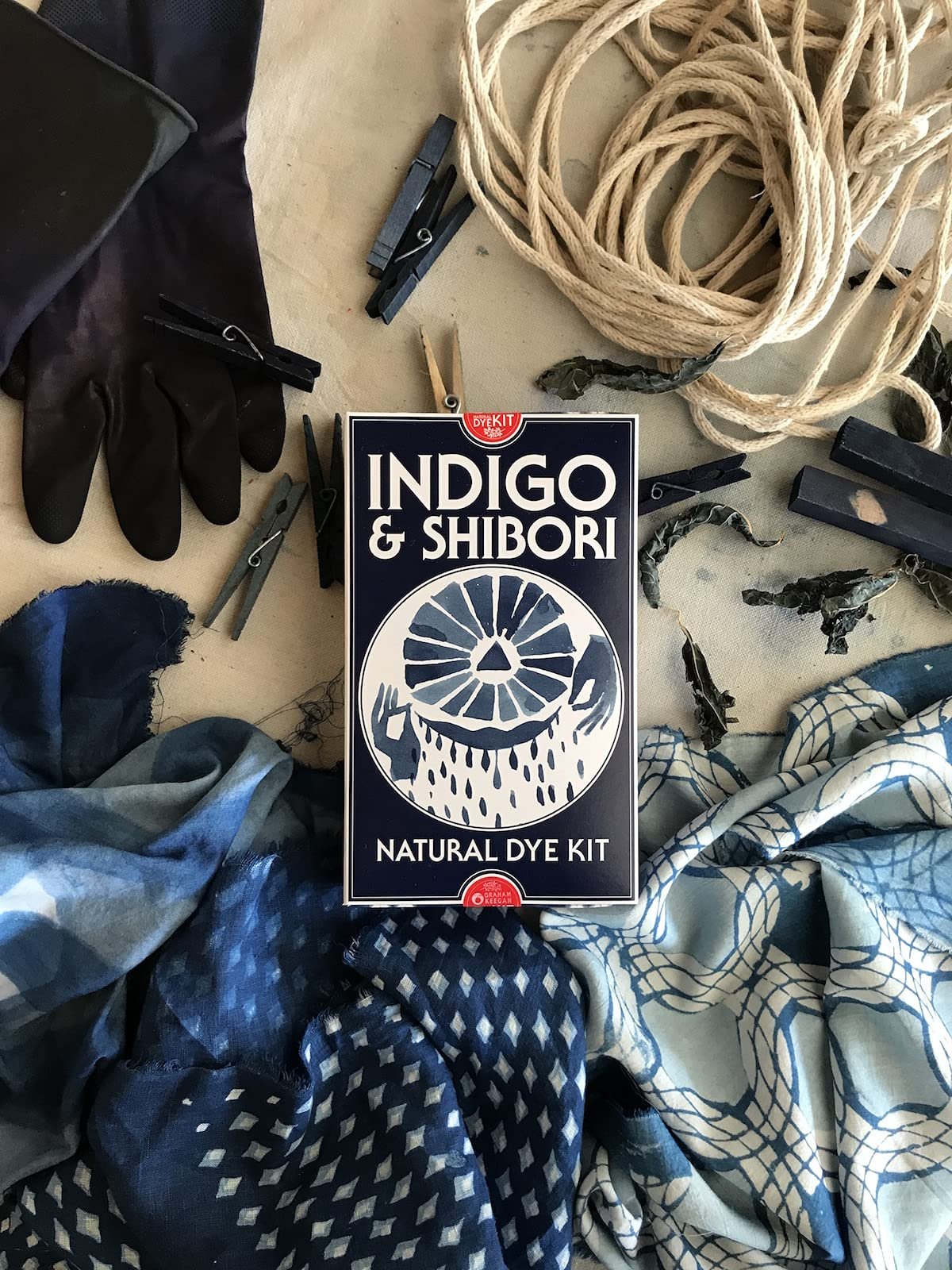

Some of the questions on this page are specific to indigo dyeing using our Indigo & Shibori Natural Dye Kit, but many are applicable to indigo dyeing more broadly!

Your dye kit comes complete with a load of supplies and materials that you can use to make designs on fabrics. Some parts of the process are complex and we may not have had room in the printed instructions included to go in depth.

If you have a question that has not yet been answered to your satisfaction, ask away!

USE KEYWORDS TO SEARCH FOR ANSWERS TO YOUR QUESTIONS

The following is an index list of each Question and Answer title, click on the title to read the corresponding Q&A, or simply use search terms in the search box above to see if your question has been answered!

-

DIP TECHNIQUE

- Jul 26, 2023 Avoiding Fading

- Jul 26, 2023 Dipping Resist Pieces

- Jul 26, 2023 Maintaining Your Whites While Rinsing

- Jul 25, 2023 Dyeing Over Multiple Days

- Jul 25, 2023 Avoiding Sediment

- Jul 25, 2023 How Sediment Affects Your Dyeing and the Importance of Proper Rinsing

- Jul 25, 2023 Tips for Using Rice Paste in a Ferrous Vat

- Jul 25, 2023 Tips for Getting the Darkest Blues

- Jul 25, 2023 Suggestions for Uneven Coloration

- Jul 25, 2023 Rinsing Stencil Print Between Dips

- Jul 25, 2023 Number of Dips for Different Shades of Indigo

- Jul 20, 2023 Avoiding Sediment in the Ferrous Indigo Vat

-

DYE GARDEN QUESTIONS

- Jul 26, 2023 Starting Indigo Seeds Indoors Versus Outdoors

- Jul 25, 2023 When to Plant Indigo Seeds

- Jul 25, 2023 Indigo Seed Propagation

-

GENERAL INDIGO DYEING QUESTIONS

- Jul 26, 2023 Calculating Amount of Indigo Needed

- Jul 25, 2023 Dyeing Protein Fibers in a Natural Indigo Vat

- Jul 25, 2023 Dyeing Stretch Fabric with Natural Indigo

- Jul 25, 2023 Ferrous Vat Longevity

- Jul 25, 2023 Shelf Life of Natural Indigo and “Pasting-Up” Your Powder

- Jul 25, 2023 Toxicity of Indigo and Indigo Dyeing

- Jul 25, 2023 Indigo and Splatter Dyeing

- Jul 25, 2023 Indigo and Cotton Velveteen

- Jul 25, 2023 Indigo and Polyester

- Jul 25, 2023 Over-dyeing with Indigo

- Jul 25, 2023 Is Indigo Dye Okay for Sensitive Skin, Is it Safe Enough to use on Baby Clothes?

- Jul 25, 2023 Light and Pale Shades of Indigo

- Jul 25, 2023 Fixing Indigo Onto Fabric

- Jul 25, 2023 Materials and Fabrics Suitable for Indigo Dyeing

- Jul 25, 2023 Disposing of a Ferrous Indigo Vat

- Jul 25, 2023 Large Container e.g. Trash Can Vat

- Jul 20, 2023 Dye Vat Capacity

-

INDIGO LEAF EXTRACTION

- Jul 25, 2023 Making a Ferrous Vat with Fresh Indigo Leaves

- Jul 25, 2023 Clarification on Indigo Extraction

-

INDIGO VAT TIPS & TROUBLESHOOTING

- Jul 26, 2023 Is the Fermentation Vat the Best Vat?

- Jul 26, 2023 Indigo Vat Troubleshooting: No Longer an Odor

- Jul 26, 2023 Indigo Vat Troubleshooting: Dark Blue Vat

- Jul 26, 2023 Indigo Vat Troubleshooting: Greenish Tint

- Jul 26, 2023 Avoiding Fading

- Jul 26, 2023 Waiting 24 Hours Between Mixing and Using Your Indigo Vat

- Jul 26, 2023 Quantity of Indigo Paste in a Vat

- Jul 26, 2023 Making a Long Term Vat

- Jul 25, 2023 Indigo Flower Comes and Goes

- Jul 25, 2023 Using Pencil to Make Marks on Fabric - Does Graphite Affect the Vat?

- Jul 25, 2023 Under-Reduced Fructose Vat

- Jul 25, 2023 Troubleshooting a Different Vat Recipe

- Jul 25, 2023 Avoiding Sediment

- Jul 25, 2023 Indigo Vat Troubleshooting: Recipe Quantities for a Large Vat

- Jul 25, 2023 Sharpening Your Vat

- Jul 25, 2023 Stirring Your Vat

- Jul 25, 2023 Adding More Pigment to a Fresh Leaf Extraction Vat

- Jul 25, 2023 Making a Vat for Pale Dyeing

- Jul 25, 2023 Sizing Up Your Vat

- Jul 25, 2023 Indigo Vat Troubleshooting: Lye and Hydrosulfite

- Jul 25, 2023 Recipe for Pickling Lime and Fructose Vat

- Jul 25, 2023 Thoughts on Using Soda Ash and Spectralite Instead of Iron and Lime in Making a Dye Vat

- Jul 25, 2023 Giving Your Vat Enough Time to Set Up

- Jul 25, 2023 Switching Reducing Agent and pH Combo When Sharpening Your Vat

- Jul 25, 2023 Vat Temperature

- Jul 25, 2023 Precision of pH for Ferrous and Fructose Vats and Indicators of Under or Over Reduction

- Jul 25, 2023 Forms of Indigo that Work in a Ferrous Vat Recipe

- Jul 25, 2023 Indigo Vat Troubleshooting: Sludge and Sediment

- Jul 25, 2023 Indigo Vat Diagnosis: Vat Color, Flower, and pH

- Jul 25, 2023 Iron Vat Temperature

- Jul 25, 2023 Dissolving Lime in an Indigo Vat

- Jul 25, 2023 Reviving a spoiled or 'oxidized' indigo dye vat

- Jul 25, 2023 Mixing and Combining New Vat Ingredients with Old or Spent Vats

- Jul 25, 2023 Indigo Vat Mixing Temperature

- Jul 25, 2023 Weak Vat, Old Vat and Vat Health Restoration

-

PRE AND POST-DYE TREATMENTS & TIPS

- Jul 26, 2023 Preventing Crocking and Dyeing Large Fabrics Like Bedding

- Jul 26, 2023 Avoiding Fading

- Jul 26, 2023 Rinsing in Still Versus Running Water

- Jul 25, 2023 How Sediment Affects Your Dyeing and the Importance of Proper Rinsing

- Jul 25, 2023 Troubleshooting Strange Fading Patterns and Discoloration

- Jul 25, 2023 Suggestions for Uneven Coloration

- Jul 25, 2023 Fabric Drying Stiff and Crispy Post-Dyeing

- Jul 25, 2023 Indigo Post-Dye Rinse: Purposes and Options

- Jul 25, 2023 Protecting Your Indigo-Dyed Pieces From Fading: Proper Scouring and Soy Milk Treatment

- Jul 25, 2023 Sun Fading of Indigo

- Jul 20, 2023 Best Way to Dry Indigo Dye

-

QUESTIONS ABOUT OUR INDIGO & SHIBORI DYE KIT

- Jul 26, 2023 Waiting 24 Hours Between Mixing and Using Your Indigo Vat

- Jul 25, 2023 Scaling Down Vat Size

- Jul 25, 2023 How Much Fabric Will the Natural Indigo & Shibori Dye Kit Dye?

- Jul 25, 2023 Ferrous Vat Longevity

- Jul 25, 2023 Components in the Natural Indigo & Shibori Dye Kit

- Jul 25, 2023 Indigo Form in the Natural Dye Kit

- Jul 25, 2023 Indigo Kit and Dyeing Large Items

- Jul 25, 2023 Light and Pale Shades of Indigo

- Jul 25, 2023 Scent of Natural Indigo

- Jul 20, 2023 Dye Vat Capacity

-

RICE PASTE

- Jul 26, 2023 Dipping Resist Pieces

- Jul 26, 2023 Pastry Cones for Applying Rice Paste Resist

- Jul 26, 2023 Indigo Resist Screen Printing

- Jul 26, 2023 Rice Paste Resist Longevity

- Jul 26, 2023 Destabilized AKA De-Fatted Bran in Rice Paste Resist

- Jul 25, 2023 Tips for Using Rice Paste in a Ferrous Vat

- Jul 25, 2023 Rinsing Stencil Print Between Dips

-

TIPS FOR VARIOUS DYE PROJECTS

- Jul 26, 2023 Preventing Crocking and Dyeing Large Fabrics Like Bedding

- Jul 26, 2023 Using Fresh Goldenrod Leaves to Make a Paintable Dye Pigment

- Jul 26, 2023 Type of Wood for Making Block Prints

- Jul 26, 2023 Mordant Recipe: Block vs Screen Printing

- Jul 26, 2023 Making a Stamp Pad

- Jul 26, 2023 Dyeing with Fresh Plants

- Jul 26, 2023 Indigo Resist Screen Printing

- Jul 26, 2023 Destabilized AKA De-Fatted Bran in Rice Paste Resist

- Jul 25, 2023 Dipping Metal in my Vat

- Jul 25, 2023 Using Natural Indigo Paste

- Jul 25, 2023 Dyeing Vegetable Tanned Leather

- Jul 25, 2023 Tips for Using Rice Paste in a Ferrous Vat

- Jul 25, 2023 Dyeing Paper

- Jul 25, 2023 Chalk and Cheesecloth Clarification in Mordant and Block Printing

-

USING MORDANTS

- Jul 26, 2023 Mixing Mordant

- Jul 26, 2023 Mordant Recipe: Block vs Screen Printing

- Jul 26, 2023 Diluting Mordant Paste

- Jul 25, 2023 Chalk and Cheesecloth Clarification in Mordant and Block Printing

Suggestions for Uneven Coloration

Q: I am getting uneven color when I am dyeing. Any suggestions?

A: Uneven coloration can be a result of many different factors. Not thoroughly scouring your fabric before dyeing can lead to uneven results. As can not agitating / moving your fabric while it is in the dye vat to ensure the liquid covers all parts of the piece equally. Also, if sediment from the bottom of the vat gets on the piece, it can block future dips in the vat from effectively transferring pigment to the piece. Just make sure to thoroughly rinse between dips to avoid this.

Fabric Drying Stiff and Crispy Post-Dyeing

Q: Sometimes my fabric feels really stiff and crispy after I dye it. Any suggestions?

A: I would make sure you are rinsing your pieces really well after dyeing them and rebalancing the pH of your fabric in a post-dye acid bath (citric acid, lemon, vinegar are some suggestions) before allowing them to dry out. Not doing so can make your fabric really stiff and crispy when it dries. As a general matter, high pHs soften cellulose fibers (soda ash on cotton, hemp, linen etc) and low pHs soften protein fibers (vinegar on silk, wool).

Precision of pH for Ferrous and Fructose Vats and Indicators of Under or Over Reduction

Q: I have seen a lot of commentary online about the necessity of getting the pH of a ferrous/fructose vat just right. Can you provide any insight on how much I need to be concerned about the precision of the pH? And how can I tell if my vat is properly reduced, is it by the color of the vat?

A: I've found that a lot of literature is over-fixated on precise pH measurements of a vat. Indigo vats actually have a lot of flexibility so long as your pH is not too low because the indigo won’t properly dissolve in a vat that is too acidic. For a home and hobby dyer, working with a ferrous or fructose vat, I've never seen any issues related to a pH that is too high (unless you are working with silk because the alkaline environment can really break down silk fibers quickly).

You really don’t need to worry about over-reduction (having a pH that is too high) in a vat reduced by iron or fructose. The only vats I've ever seen that are over-reduced are those that have an industrial reducing agent like thiourea dioxide and lye. They will turn pee-yellow to pale yellow/white and literally strip indigo off of well-dyed pieces. I have never seen a ferrous or a fructose vat do that.

As for under-reduction (having a pH that is too low), the color of your vat is not an indicator of under-reduction as different reducing agents color the liquor differently. Generally, what you are looking for is the transparency and darkness/lightness of the liquid rather than the color: if the liquid is transparent and not mid to dark green or blue, it is going to transfer any available indigo pigment well. If the liquid in your vat is opaque and dark that is an indicator that the pH is too low and it needs more reduction. If you try to dye in an under-reduced vat your blues will appear dull.

Clarification on Indigo Extraction

Q: I have a question about getting indigo pigment from the indigo I grew. I saw the PDF you have on your website where you alkalize and oxidize. At the end it says to prepare your vat or let dry. How do you dry? Do you leave it in the container with the lid open? I also was wondering if the size of container mattered? Is it better to do in small batches instead of a large amount? Also, how long is the shelf-life of the extracted pigment if I am not yet ready to make my vat?

A: If you let your pigment settle for a few days you can pour off the liquid on top. You can then put the remaining concentrate in a container and further boil it off or just let it sit out to dry. There’s an indefinite shelf-life so no rush to make your vat. Just keep the dried sediment in a jar in a cool place and out of the sun.

I would suggest doing bigger batches if you can. Small batches yield verrrrry little pigment each so the bigger the batch, the fewer times you’ll have to do the process!

There are some posts on my Instagram (@yesgraham) with shots of the indigo extraction process. You can also find information from other folks on Instagram using these tags as well: #indigoextraction2017, #indigoextraction2018, and #indigoextraction2019.

When to Plant Indigo Seeds

Q: I have seen in many articles that that Indigo Persicaria Tinctoria is sensitive to frost. When should I plant my indigo seeds?

A: I live in Los Angeles and I germinate my indigo seeds in late December/January under a grow-light and transplant in February. However there is NO frost in Los Angeles. If there is even a tiny frost, it will kill the plants back to the root (or thick stems if the plant is more mature). I'd recommend waiting to transplant until there is zero chance of a frost. Seeds could be planted 6-8 weeks before transplant.

Chalk and Cheesecloth Clarification in Mordant and Block Printing

Q: I am looking to try block printing and your article on mordant printing looks like a great place to start! In this article you reference using chalk but I’m not sure what exact material you mean when you say chalk. Also, is the cheesecloth meant to wrap the printing pad or the printing block?

A: When I make reference to chalk I am referring to Calcium Carbonate.

The cheesecloth is used to wrap around the print pad but really any open weave fabric will work. I’ve used everything from a loose weave rayon to silk screen fabric.

Indigo Post-Dye Rinse: Purposes and Options

Q: Your kit uses citric acid as a post-dye-rinse. Why is this necessary and can I use something different as a post-dye-rinse?

A: Dipping your fabric in a citric acid bath after dyeing rebalances the pH of your fabric and sets the indigo pigment. For an indigo post-dye rinse, any acidic household product will work: lemons and vinegar are two easy ones. Simply add some to water and submerge your piece and agitate for a few minutes. Then follow with a water rinse and a laundering.

For vinegar, you can use approximately half a cup per one gallon of water. For lemons I recommend one squeezed whole lemon per gallon of water.

Forms of Indigo that Work in a Ferrous Vat Recipe

Q: I’ve been using a pre-reduced indigo vat with thiox and soda ash and I would like to stay away from the thiox. Do you know if I can use the iron vat directions with the pre-reduced indigo in place of pure indigo powder?

A: Yes, the ferrous vat recipe will work with any kind of indigo : organic, synthetic, pre-reduced, paste, dried, you name it. In all cases I recommend pasting up your indigo - shaking vigorously in a container with smooth stones or marbles and just enough water to hydrate your powder into a paste prior to adding it to the vat. You can scale the amount of indigo you use based on how strong you want your vat and what concentration of pigment you’re working with.

Indigo Form in the Natural Dye Kit

Q: Is the indigo in your Indigo & Shibori Natural Dye Kit in powder form or paste form? Is it pre-reduced?

A: The indigo itself is in a paste slurry form that has never been dried, so there is no challenge (as there is with fully dried indigo) in getting it hydrated.

It is not pre-reduced which means it needs to be mixed with two other ingredients (included in the kit) that activate the indigo pigment into an indigo dye.

Indigo Vat Troubleshooting: Sludge and Sediment

Q: I was wondering if you may be able to help me troubleshoot my 5 gallon indigo vat issues? I purchased your beginners kit and all was working out well. Then, after a week or so my vat was just dark blue/ gray in appearance and the new fabrics were taking on a little blue pigment, but not really getting darker after many dips. I thought maybe the vat became oxidized, so I tried to follow your steps to solving oxidation (decant a gallon, heat to 180F, add 66 g iron and 100 g lime, used an immersion blender to mix). After adding that to the original vat and mixing all, my vat looked brownish in color, like mud/sludge. I let it to settle over night and it looks separated, clear like liquid on top and I see brownish sludge starting about half way down, taking up the bottom half of the 5 gallon indigo vat.

Might you have an idea of what is happening and how I might be able to fix/ revive my vat? I did measure my fabrics and I believe I have only dipped about 3.3 pounds in total (cotton/ linen).

A: I’m now a firm proponent of reheating the entire vat as a way to revive it. I use stainless steel pots and this is one of the only really logistically uncomplicated ways of doing this. So I would recommend getting yourself a stainless steel pot 25 to 30 quart, if you don’t already have one.

If you raise the temperature of the entire vat up to about 125 degrees while stirring every few minutes to keep the sediment up in suspension, you’ll see that the vat really “comes back to life”. Once it is up to temp, I cut the heat and let the sediment settle (for at least an hour and probably two hours is better). Then I dye in the clear liquid at the top.

There is also a possibility that you’ve exhausted all of your pigment depending on how much coverage (and how dark) you’ve dyed your pieces.

Indigo Vat Troubleshooting: Tips on Sediment and Sharpening Your Vat

Q: I mixed up all the ingredients using only a gallon or so of hot tap water and noticed that there was a lot of sludge at the bottom of the container. The indigo and iron seemed to dissolve but the lime made the liquid look ‘milky’ and thick. Should I not pour the sludge into the vat?

A: The sediment is good! It is the active medium for the reduction (activation) of the indigo. It is a necessary part of the ferrous vat. That said, it is good to make sure that this sediment has settled out into your final vat before dyeing - as it can stain fabric when it has first been mixed up as it contains iron. The stains can be removed with citric acid and soap. I only dye a handful of things each day and always stir up the vat after dyeing and allow it to settle out before dyeing again.

Indigo Vat Diagnosis: Vat Color, Flower, and pH

Q: The color of my vat before stirring looks bluish-gray-brown. There is a shimmery copper color on the surface of the vat, but no flower. When I take a pH reading the strip says that the liquid is higher than pH 11. Should I add more iron and lime even though the pH is so high?

A: The vat color can range and still be within working order, so first things first, I’d recommend stirring the vat thoroughly for about 30 seconds to get all the sediment up and moving so you can see what color the SEDIMENT is. If it is green/yellow, the flower will reform and you’ll be good to dye in an hour or so after the sediment settles back out. If the sediment is blue green or green grey, I’d recommend ‘sharpening’ with another 50g iron and 75g lime.

In the Ferrous vat, the pH is not particularly relevant - if it isn’t working, the answer is often ‘just add more iron and lime’.

To do that, decant as much of the vat liquid as possible (into some large stock pot) and heat that up to a simmer then add those ingredients.

Recombine everything, stir it all up so it’s properly mixed, then let it settle.

Always wait AT LEAST an hour (three is better) after stirring to dye to let all the sediment settle. The chalky green/gray/blue color on the fabrics comes from contact with the sediment. It needs to be blasted (hose) and/or washed off the fabric with soapy water (bar soap is best) before trying to dye again. The blue should ‘clean up’.

Iron Vat Temperature

Q: What temperature should my iron vat be? I’ve heard you mention boiling the water for the vat, but also heard you refer to using the vat cold or at room temperature.

A: The ferrous vat can work at both cold and warm temperatures. I typically re-heat to about 125F after a long dye session and then allow it to cool before dyeing.

Protecting Your Indigo-Dyed Pieces From Fading: Proper Scouring and Soy Milk Treatment

Q: Are there ways to protect my indigo-dyed fabrics from fading? It seems like some of my indigo-dyed fabrics have faded from being dried in the sun - is that possible?

I've heard that soy can be used to help fix the indigo pigment. Can you let me know how to do this?

A: Fading can happen on indigo dyed pieces for a number of reasons: incomplete or insufficient scouring of fabric prior to dyeing, under-reduced vat conditions resulting in weakly adhered dye to fiber, ultraviolet light as well as ozone exposure. As a general matter, if you are drying your pieces outside keep them in the shade whenever possible. Indigo is very susceptible to fading when it is exposed to UV light while wet.

For long lasting blues, first, make sure your fabric is totally scoured prior to dyeing : boil it in soda ash for at least 4 hours, then rinse thoroughly. Cotton (and other natural cellulose fibers) are often sheathed in waxes and pectins which are not ideal bonding sites for indigo because they can (and eventually will) separate from the cellulose fibers themselves, taking any indigo attached to them. Properly scoured fabric is free of these compounds and you’ll find that those fabrics dye more easily, evenly and the colors hold up best.

And yes, soy milk treatments can add a layer of protection against crocking (fading from rubbing) and UV exposure by (to my knowledge) adding a protein “glazing” to the piece.

When I do soy milk treatments, I make the soy milk from scratch. I soak the beans for 24 hours, blend in the excess water, strain off the solids, and use the liquid. I suggest making your own soy milk as well. Purchased soy milk has gone through a number of processes to make it shelf stable and it contains other ingredients. I don’t have enough experience to say for sure that purchased soy milk would not work as well as homemade soy milk, but I do know that it smells and feels different than fresh soy milk.

To treat your piece, dip it into the milk to wet it and then wring the piece out and allow it to dry flat. You will want to rotate the piece periodically as it dries otherwise the fabric has a tendency to stick to whatever surface it is on.

Dissolving Lime in an Indigo Vat

Q: I am mixing up an indigo vat and am finding that the lime doesn't want to completely dissolve. There is quite a bit of sediment. I used hot water (120 degrees). Any suggestions?

A: Lime is not fully soluble in water! There is always a sediment when working with calcium hydroxide. No need to worry, you’re doing it right.

Indigo Kit and Dyeing Large Items

Q: I bought your Indigo & Shibori Natural Dye Kit. Would it work to dye a blanket or other large item?

A: The kit certainly has the ability to dye large items, but it is designed for creating repeat patterns on smaller (or bundled) pieces of fabric by folding the pieces into smaller shapes and dipping those as opposed to over-dyeing large pieces. All-over dyed pieces will tend to be mottled and uneven in the color uptake when dyed in a relatively small amount of liquid like the 5 gallons the kit is designed to produce. When dyeing large items I prefer to dye in vats that are 25-50 gallons and typically larger indigo-dyed items with all-over coverage (like jeans) are dyed in the yarn and then woven. Large items are rarely dyed in natural indigo vats because of the challenge.

Indigo and Splatter Dyeing

Q: Can I use a paint brush or toothbrush to splatter dye with indigo?

A: Splatter dyeing doesn’t work for indigo because of a particular quirk in how the dye is activated. To actually get the dye to adhere to fabric, it needs to be in a “reduced” chemical state. The action of splattering the indigo exposes it to lots of air and oxygen and makes it essentially inert before it hits the fabric. The blue flecks would stain the fabric but after a couple washes and some time in the air, the color would fade right off. To get the color onto the cloth the pieces have to be immersed in the dye.

Indigo Seed Propagation

Q: I grew some indigo plants, can you tell me how to propagate seeds from my plants?

A: In Los Angeles I’ll start harvesting seeds by the middle of July, but if you are in a colder climate like the northeast, they don’t typically mature until around Thanksgiving. I do this by rooting any stems that are flowering in water indoors and letting them complete their cycle out of the soil, which they’re surprisingly happy to do.

I trim my seed bearing stalks from plants as the seeds mature and bundle them and invert them and hang them to dry. Birds and mice love to eat the seeds so make sure to dry and store them out of reach!

Once the stalk is crispy, I will stomp or hand crush all the seed groups and begin sieveing things to remove leaves and stems and dried flower bits. I then roll the seeds between leather sheets to strip them clean, though this is not necessary for germination. I’ll then wind winnow what remains to separate the lighter and immature seed from the bulky growers! I germinate in bulk trays and thin/transplant as needed.

Indigo and Cotton Velveteen

Q: Is cotton velveteen suitable for dyeing with indigo?

A: Yes, that should dye very well! Natural indigo works well on natural fibers from plants or animals.

Because cotton velveteen is a thick and very absorbent fabric, be sure to exit the vat very slowly to give it adequate time to drain back into the dye pot between dips. Otherwise, it will act like a sponge and carry a lot of the vat liquid out with it. Don’t wring/drip through the air. Best to wring the piece out while it is still under the surface of the vat and then raise it up and out, then release the tension.

Indigo and Polyester

Q: Can I dye polyester fabric using natural indigo dye?

A: Natural indigo vats do not effectively dye polyester. It seems the indigo pigment molecule doesn’t have a way to properly bond to polyesters. I’ve gotten blue-greys dyeing polyester in the past but they don’t look great and are never that saturated and tend to wash and sun fade very easily. Natural indigo works best on natural fibers from plants or animals. You will even notice that if you dye a garment that is made of natural fibers (say, cotton) but is stitched using polyester thread, the fabric will dye but the thread will stay more or less white.