INDIGO DYEING : Questions & Answers

Some of the questions on this page are specific to indigo dyeing using our Indigo & Shibori Natural Dye Kit, but many are applicable to indigo dyeing more broadly!

Your dye kit comes complete with a load of supplies and materials that you can use to make designs on fabrics. Some parts of the process are complex and we may not have had room in the printed instructions included to go in depth.

If you have a question that has not yet been answered to your satisfaction, ask away!

USE KEYWORDS TO SEARCH FOR ANSWERS TO YOUR QUESTIONS

The following is an index list of each Question and Answer title, click on the title to read the corresponding Q&A, or simply use search terms in the search box above to see if your question has been answered!

-

DIP TECHNIQUE

- Jul 26, 2023 Avoiding Fading

- Jul 26, 2023 Dipping Resist Pieces

- Jul 26, 2023 Maintaining Your Whites While Rinsing

- Jul 25, 2023 Dyeing Over Multiple Days

- Jul 25, 2023 Avoiding Sediment

- Jul 25, 2023 How Sediment Affects Your Dyeing and the Importance of Proper Rinsing

- Jul 25, 2023 Tips for Using Rice Paste in a Ferrous Vat

- Jul 25, 2023 Tips for Getting the Darkest Blues

- Jul 25, 2023 Suggestions for Uneven Coloration

- Jul 25, 2023 Rinsing Stencil Print Between Dips

- Jul 25, 2023 Number of Dips for Different Shades of Indigo

- Jul 20, 2023 Avoiding Sediment in the Ferrous Indigo Vat

-

DYE GARDEN QUESTIONS

- Jul 26, 2023 Starting Indigo Seeds Indoors Versus Outdoors

- Jul 25, 2023 When to Plant Indigo Seeds

- Jul 25, 2023 Indigo Seed Propagation

-

GENERAL INDIGO DYEING QUESTIONS

- Jul 26, 2023 Calculating Amount of Indigo Needed

- Jul 25, 2023 Dyeing Protein Fibers in a Natural Indigo Vat

- Jul 25, 2023 Dyeing Stretch Fabric with Natural Indigo

- Jul 25, 2023 Ferrous Vat Longevity

- Jul 25, 2023 Shelf Life of Natural Indigo and “Pasting-Up” Your Powder

- Jul 25, 2023 Toxicity of Indigo and Indigo Dyeing

- Jul 25, 2023 Indigo and Splatter Dyeing

- Jul 25, 2023 Indigo and Cotton Velveteen

- Jul 25, 2023 Indigo and Polyester

- Jul 25, 2023 Over-dyeing with Indigo

- Jul 25, 2023 Is Indigo Dye Okay for Sensitive Skin, Is it Safe Enough to use on Baby Clothes?

- Jul 25, 2023 Light and Pale Shades of Indigo

- Jul 25, 2023 Fixing Indigo Onto Fabric

- Jul 25, 2023 Materials and Fabrics Suitable for Indigo Dyeing

- Jul 25, 2023 Disposing of a Ferrous Indigo Vat

- Jul 25, 2023 Large Container e.g. Trash Can Vat

- Jul 20, 2023 Dye Vat Capacity

-

INDIGO LEAF EXTRACTION

- Jul 25, 2023 Making a Ferrous Vat with Fresh Indigo Leaves

- Jul 25, 2023 Clarification on Indigo Extraction

-

INDIGO VAT TIPS & TROUBLESHOOTING

- Jul 26, 2023 Is the Fermentation Vat the Best Vat?

- Jul 26, 2023 Indigo Vat Troubleshooting: No Longer an Odor

- Jul 26, 2023 Indigo Vat Troubleshooting: Dark Blue Vat

- Jul 26, 2023 Indigo Vat Troubleshooting: Greenish Tint

- Jul 26, 2023 Avoiding Fading

- Jul 26, 2023 Waiting 24 Hours Between Mixing and Using Your Indigo Vat

- Jul 26, 2023 Quantity of Indigo Paste in a Vat

- Jul 26, 2023 Making a Long Term Vat

- Jul 25, 2023 Indigo Flower Comes and Goes

- Jul 25, 2023 Using Pencil to Make Marks on Fabric - Does Graphite Affect the Vat?

- Jul 25, 2023 Under-Reduced Fructose Vat

- Jul 25, 2023 Troubleshooting a Different Vat Recipe

- Jul 25, 2023 Avoiding Sediment

- Jul 25, 2023 Indigo Vat Troubleshooting: Recipe Quantities for a Large Vat

- Jul 25, 2023 Sharpening Your Vat

- Jul 25, 2023 Stirring Your Vat

- Jul 25, 2023 Adding More Pigment to a Fresh Leaf Extraction Vat

- Jul 25, 2023 Making a Vat for Pale Dyeing

- Jul 25, 2023 Sizing Up Your Vat

- Jul 25, 2023 Indigo Vat Troubleshooting: Lye and Hydrosulfite

- Jul 25, 2023 Recipe for Pickling Lime and Fructose Vat

- Jul 25, 2023 Thoughts on Using Soda Ash and Spectralite Instead of Iron and Lime in Making a Dye Vat

- Jul 25, 2023 Giving Your Vat Enough Time to Set Up

- Jul 25, 2023 Switching Reducing Agent and pH Combo When Sharpening Your Vat

- Jul 25, 2023 Vat Temperature

- Jul 25, 2023 Precision of pH for Ferrous and Fructose Vats and Indicators of Under or Over Reduction

- Jul 25, 2023 Forms of Indigo that Work in a Ferrous Vat Recipe

- Jul 25, 2023 Indigo Vat Troubleshooting: Sludge and Sediment

- Jul 25, 2023 Indigo Vat Diagnosis: Vat Color, Flower, and pH

- Jul 25, 2023 Iron Vat Temperature

- Jul 25, 2023 Dissolving Lime in an Indigo Vat

- Jul 25, 2023 Reviving a spoiled or 'oxidized' indigo dye vat

- Jul 25, 2023 Mixing and Combining New Vat Ingredients with Old or Spent Vats

- Jul 25, 2023 Indigo Vat Mixing Temperature

- Jul 25, 2023 Weak Vat, Old Vat and Vat Health Restoration

-

PRE AND POST-DYE TREATMENTS & TIPS

- Jul 26, 2023 Preventing Crocking and Dyeing Large Fabrics Like Bedding

- Jul 26, 2023 Avoiding Fading

- Jul 26, 2023 Rinsing in Still Versus Running Water

- Jul 25, 2023 How Sediment Affects Your Dyeing and the Importance of Proper Rinsing

- Jul 25, 2023 Troubleshooting Strange Fading Patterns and Discoloration

- Jul 25, 2023 Suggestions for Uneven Coloration

- Jul 25, 2023 Fabric Drying Stiff and Crispy Post-Dyeing

- Jul 25, 2023 Indigo Post-Dye Rinse: Purposes and Options

- Jul 25, 2023 Protecting Your Indigo-Dyed Pieces From Fading: Proper Scouring and Soy Milk Treatment

- Jul 25, 2023 Sun Fading of Indigo

- Jul 20, 2023 Best Way to Dry Indigo Dye

-

QUESTIONS ABOUT OUR INDIGO & SHIBORI DYE KIT

- Jul 26, 2023 Waiting 24 Hours Between Mixing and Using Your Indigo Vat

- Jul 25, 2023 Scaling Down Vat Size

- Jul 25, 2023 How Much Fabric Will the Natural Indigo & Shibori Dye Kit Dye?

- Jul 25, 2023 Ferrous Vat Longevity

- Jul 25, 2023 Components in the Natural Indigo & Shibori Dye Kit

- Jul 25, 2023 Indigo Form in the Natural Dye Kit

- Jul 25, 2023 Indigo Kit and Dyeing Large Items

- Jul 25, 2023 Light and Pale Shades of Indigo

- Jul 25, 2023 Scent of Natural Indigo

- Jul 20, 2023 Dye Vat Capacity

-

RICE PASTE

- Jul 26, 2023 Dipping Resist Pieces

- Jul 26, 2023 Pastry Cones for Applying Rice Paste Resist

- Jul 26, 2023 Indigo Resist Screen Printing

- Jul 26, 2023 Rice Paste Resist Longevity

- Jul 26, 2023 Destabilized AKA De-Fatted Bran in Rice Paste Resist

- Jul 25, 2023 Tips for Using Rice Paste in a Ferrous Vat

- Jul 25, 2023 Rinsing Stencil Print Between Dips

-

TIPS FOR VARIOUS DYE PROJECTS

- Jul 26, 2023 Preventing Crocking and Dyeing Large Fabrics Like Bedding

- Jul 26, 2023 Using Fresh Goldenrod Leaves to Make a Paintable Dye Pigment

- Jul 26, 2023 Type of Wood for Making Block Prints

- Jul 26, 2023 Mordant Recipe: Block vs Screen Printing

- Jul 26, 2023 Making a Stamp Pad

- Jul 26, 2023 Dyeing with Fresh Plants

- Jul 26, 2023 Indigo Resist Screen Printing

- Jul 26, 2023 Destabilized AKA De-Fatted Bran in Rice Paste Resist

- Jul 25, 2023 Dipping Metal in my Vat

- Jul 25, 2023 Using Natural Indigo Paste

- Jul 25, 2023 Dyeing Vegetable Tanned Leather

- Jul 25, 2023 Tips for Using Rice Paste in a Ferrous Vat

- Jul 25, 2023 Dyeing Paper

- Jul 25, 2023 Chalk and Cheesecloth Clarification in Mordant and Block Printing

-

USING MORDANTS

- Jul 26, 2023 Mixing Mordant

- Jul 26, 2023 Mordant Recipe: Block vs Screen Printing

- Jul 26, 2023 Diluting Mordant Paste

- Jul 25, 2023 Chalk and Cheesecloth Clarification in Mordant and Block Printing

Rinsing Stencil Print Between Dips

Q: I am curious why it is necessary to rinse your fabric after each dip when using the iron vat? As I'll be doing a lot of stencil dyeing I am wondering if the rinsing will become an issue with the paste coming off.

A: I don’t typically rinse between dips with the paste dips because it will rinse off. However, if my piece hits the sediment in the ferrous vat, I DO rinse. Make sure you are dyeing in a very deep vat so that your fabric can hang freely in the liquid and not touch the sediment. For dark results, stick to 2-3 dips per day so the rice has a chance to dry out and stay firm. I rinse between dips for a couple reasons : first, it helps to oxidize the indigo more quickly and thoroughly, second, it rinses off any sludge, sediment or flower that may be trapped on the piece or in the crevices which would act as a resist for future dips.

Reviving a spoiled or 'oxidized' indigo dye vat

Q: I tried your kit as a newbie and I definitely made mistakes... I didn't rinse between the dips, and I was ringing the pieces out into the vat as I took them out. I'm pretty sure I oxidized the vat and ended up with some anemic pieces. After only 3 dips, nothing was dyeing anymore, they were not getting any darker. I ran out of time and gave up, but I kept the vat and closed it with an air-tight lid in a bucket.

My question is, can I rejuvenate these vats after they've been sitting for a couple of weeks? I wasn't sure if time would break it down to be useless, or if I can rescue the indigo that's still in there?

I thought I would start with a fresh vat, but after reading your tips... maybe I can still use what I have and try to get the pieces darker?

A: Yes, you can definitely rejuvenate the vat! I go more in depth about the process of sharpening here : www.grahamkeegan.com/indigo-vat-basics but in short, there are two main ways to sharpen your vat.

First, I would simply try heating your vat. If you used a pot or steel container (or can transfer the contents of your vat into one) you can heat the contents up to about 130° Fahrenheit and hold the temperature there for a half hour or so, stirring every five minutes. If you still have residual indigo, ferrous sulfate and lime in your sediment, the vat should soon form a purple coppery skin and the sediment may lighten up in color from a dull gray to a rich green. Stir your vat, cut the heat and allow the sediment to settle out before attempting to dye again.

Second, add more iron and lime. Those two ingredients are what activate the indigo in the vat and it sounds like you haven’t actually exhausted all the color from the vat, you’ve just inactivated the indigo by recombining oxygen with the dye liquor. To sharpen a 5 gallon vat, add 50g iron and 75g slaked lime into a quart of boiling water, immersion blend (ideally), or mix thoroughly. Once the ingredients are fully incorporated (and will appear as a grey/green slurry) add that to the inactive vat and stir to fully mix it in. Let the vat sit overnight, stirring every few hours (or when you remember to). The sediment in the vat should change from a dark gray green to a lighter forest or grass green and the bubbles on the top of the vat will have a purple coppery skin. The liquid of the vat itself will be anywhere between russet, yellow to green colored when it is ready to dye.

Over-dyeing with Indigo

Q: I spilled paint on my dress. I’d like to dye it to a nice dark blue. Can I use indigo to dye over everything?

A: I wouldn’t hold out much hope for a natural over-dye solving a paint spill problem as natural dyes won’t bond well to synthetic materials (paint/plastic). Your fabric may get darker, but the places where the paint are would more than likely stay the same color.

Is Indigo Dye Okay for Sensitive Skin, Is it Safe Enough to use on Baby Clothes?

Q: Is natural indigo safe to use on baby clothing and accessories? I was hoping to dye some onesies and swaddles with the indigo.

A: In all my years of experience researching and working with Indigo, I have never heard of any allergies or even cautions for humans for any age regarding the natural indigo pigment molecule. The kits have been used at many a baby shower and dyed countless onesies, blankets and sheet sets.

Light and Pale Shades of Indigo

Q: What is your recommended amount of indigo for a five gallon vat if I wanted a pale blue, not a dark blue?

A: The kit comes with a bottle containing 50g of indigo extract. This is plenty to make a very saturated blue dye achievable with only a half dozen dips or so. If you would like a paler blue, it is best to get there with the same number of dips, though each dip will only be a baby step toward deep indigo as opposed to using the full strength of the vat. So, you can mix up the vat as normal (same amount of water, all the iron, all the lime) and simply add 1/4 of the indigo. This will produce a weak vat. When you layer many dips in this vat, you'll get some wondrously rich pale blues. You can save the indigo for later addition or for another vat.

Mixing and Combining New Vat Ingredients with Old or Spent Vats

Q: I purchased a Indigo dye From Dharma Trading which is supplied by Jacquard company and the dye flower did not form very well and I found that the pieces that I dyed faded out almost to white which was very strange, after creating beautiful pieces, this was heartbreaking! So don't know if that was inferior dye or ash or what it could be?! Since I already have a vat going do you think I should just add the items in your kit to my present vat or start over!

A: The three ingredients that Jacquard uses for their vat are synthetic pre-reduced Indigo (blue bottle), Soda Ash (Granular white powder) and Thiourea Dioxide (Thiox, finer white powder). I have to assume, because your flower didn't form well and your pigment washed out, that your problem was with the Thiox, which is the reducing agent in the vat. Its job is to modify the indigo molecule so that it will elect to bond with your fabric. If this chemical is compromised, your pigment will never be fully reduced and your vat will not turn yellow/green. The strength of thiox will degrade when it is exposed to air. Perhaps your baggie of it was old, a bad batch, or wasn't tightly sealed.

The Indigo & Shibori natural dye kit can certainly be added to this vat and the two should work in concert and give nice rich dark shades! The Natural dye kit kit uses different ingredients (Natural Indigo from Plants, Slaked Lime and Ferrous Sulfate). It is great for plant fibers, but its strength can damage animal fibers like silk and wool. So consider that before dyeing

Number of Dips for Different Shades of Indigo

Q: How many times do I have to dip to get a super dark indigo?!

A: This dip-o-meter was produced using the Indigo & Shibori Kit. As you can see, each dip adds a bit more pigment to the piece. The earlier dips were as short as 20 seconds, while the later dips lasted as long as 10 minutes.

Fixing Indigo Onto Fabric

Q: How do I set the indigo dye?

A: Quick answer : Air and something acidic.

Long answer : Indigo is a vat dye. The pigment molecules adhere to the fabric when they are in an elevated pH and chemically reduced (devoid of oxygen molecules in this case). When the fabric is reintroduced to the chemicals in our atmosphere (namely the oxygen in air) it oxidizes, turning from leuco-indigo to indigotin by incorporating oxygen. The when entirely blue, the piece then needs to be rinsed of all excess pigment and submerged in an acidic bath. The Indigo & Shibori Natural Dye Kit includes a packet of citric acid which can be used to create a rinsing bath for your work. Citric acid in water is historically called a "Sour Bath." This sour bath will bring the pH of your goods down from the pH11+ conditions of the indigo vat. Many other acids can be used including vinegar, lemon juice (essentially liquid citric acid), or strongly steeped black tea.

For longevity of your dyed goods, a soy post-treatment can help to protect from wear and UV exposure, see the Q&A for Sun Fading of Indigo for more information.

Indigo Vat Mixing Temperature

Q: Do I need to use hot water to prepare my vat?

A: No. You can use cold, warm or hot water. The warmer the water, the quicker the reaction between the lime, iron and indigo will occur. I've had vats ready to dye in as little as an hour with very hot water, but a cold water preparation works exactly the same, just takes longer to develop at around 24 hours.

Scent of Natural Indigo

A: A natural indigo vat has a unique smell somewhere between earthy, musty, smoky with a hint of grass and manure!

The indigo pigment that comes in your bottle is actually a fermented extract from a plant. As a result, different seasons and batches of indigo, as well as indigo from other locations will have varying smells. Different vat preparations also create different smells and believe it or not, this vat style, known as the iron vat, has the least smell!

After your dyed goods are rinsed in the citric acid solution and washed, the smell fades.

Materials and Fabrics Suitable for Indigo Dyeing

Q: Is cotton a good type of cloth to dye? Are certain fabrics more suited to indigo dye than others?

A: Yes, cotton would be great! In fact, the bandana that's included in the kit is 100% cotton.

The indigo vat style provided in this natural dye kit is know as the iron vat and contains ferrous sulfate and lime, both of which can be damaging to finer protein fibers like wool and silk. If you would like to dye with protein fibers, make sure to avoid the sediment which settles at the bottom of the vat. If you make contact with the sediment, thoroughly rinse your piece as soon as possible. As soon as you are finished dyeing any protein fibers, before they have had a chance to dry, make sure that you THOROUGHLY rinse in cold and warm water and pH balance them. I recommend a prolonged soak (half hour or so) in a solution of 1/4 cup vinegar (any 5% acetic acid variety will do) to one gallon of water, agitating occasionally to restore the pH of your item to slightly acidic.

All plant based fibers work exceptionally well in this vat style, that includes bamboo, cotton, hemp, linen, ramie, rayon, etc. And as you'll see when using the clamps included with the kit, even wood dyes very well! These cellulose based fibers are more amenable to dyeing in the alkaline conditions of the indigo vat. When you’ve finished dyeing with them, do make sure to pH balance as well though, using the citric acid included in the kit.

Synthetic fibers like polyester, nylon and nylon, rubber, neoprene, etc. do not dye well.

Disposing of a Ferrous Indigo Vat

Q: How do I dispose of my indigo vat?

A: Your natural dye kit indigo vat contains these three ingredients : Indigo Pigment (an organic molecule), Ferrous Sulfate (100g) and Hydrated Lime (150g). Both of these compounds are traditional soil amendments for trees and lawns.

There are two recommended methods for disposal, both start with this step :

When your vat is exhausted (you've pulled all the pigment out that you can) whisk air into the vat (a huge no-no when you're trying to dye). This will introduce Carbonic Acid (dissolved Carbon Dioxide) into the solution, neutralizing the pH and converting most of the Lime to Gypsum.

1) If you are on a septic system : Do not dispose of any liquid down your drain, instead, dilute your vat to 1/4 strength and disperse evenly on a lawn or the ground at the base of trees and shrubs. If you have iron deficient soils, this can help green your plants (http://homeguides.sfgate.com/add-iron-garden-soil-95549.html)

2) If you do not have available green space, or are on a municipal sewage system : Allow your whisked vat to settle out. Pour the opaque blue liquid down the toilet being careful not to allow sediment to flow out. Dispose of the remaining chalky sediment in the trash.

Sun Fading of Indigo

Q: Will sun fade the indigo? I noticed my indigo was a lot darker when I first placed it on the line to dry.

A: Yes, sun will naturally fade indigo. However, it takes days, weeks and months of UV exposure to remove substantial amounts of color. It sounds like you're describing the process of lightening that naturally happens when the piece dries out. Wet indigo dyed textiles always appears darker than the same fabric when dry. I recommend two or three more dips in the indigo vat AFTER you see the fabric reach the shade that you want.

Re: actual sun fading of indigo dyed textiles : In John Marshall’s book Singing The Blues (which I highly recommend as a practical guide to working with indigo), he published photos of fabrics that have been exposed to comparable amounts of sunlight. One piece of fabric had been treated with a soy-milk after bath, the other received no such treatment. The fabric which received a layer of soy milk following dyeing was appreciably better at resisting the UV fading effects of the sun. I’m now firmly in support of dipping all my own indigo dyed textiles in a solution of soy milk (I’ll make my own from whole soy beans if I have the time, but will also use pure, no-sugar-or-flavor-added bottled soymilk) after their pH balancing rinse and allowing the soy to dry on the fabric. I won’t wash the item for a month to allow the soy to properly cure onto the fabric.

Weak Vat, Old Vat and Vat Health Restoration

Q: My Indigo vat no longer has a flower and is no longer yellow-greenish. When I dye, the cotton reacts blueish and not greenish. How do I keep the vat healthy? Do I need to warm it up?

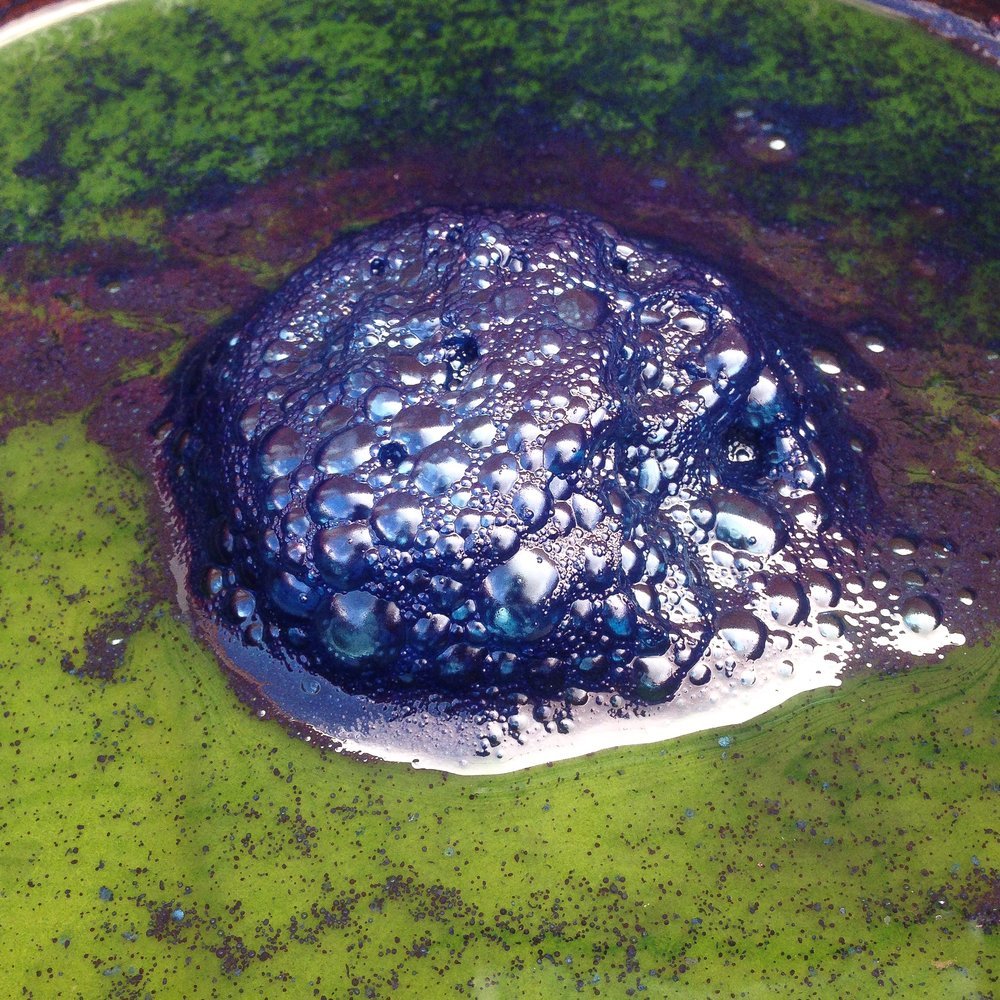

A: Take a look at the photos below. One shows the surface of a spent vat, the other is a healthy vat that was just mixed up complete with a flower and yellow-green sediment that needs to be allowed to settle out before dyeing. Eventually all vats will become exhausted and will need disposing.

When your vat begins to look opaque green/blue or blue/grey, you need to stop dyeing or rehabilitate your vat via a process called 'sharpening'. If your vat is dark and opaque, no more pigment will transfer onto your piece, no matter how long, or how many times you dip. That said, you probably still have some residual pigment left in the vat, it is just not in proper shape to transfer onto the fabric.

You do not NEED to heat your vat, or warm it up, to sharpen it, but it will help! If you have made your vat in a large metal container, you can place it on the stove and bring the contents up to a simmer, this will induce your vat back into a state of reduction and you’ll be able to transfer more color from the vat onto your fabric.

For information about sharpening your vat and extracting more dye, feel free to take a look at this page that goes into more depth.

Large Container e.g. Trash Can Vat

Q: I have had great results working in a 5 gallon container but want to be able to dye yardage and large pieces. I've never dyed in a larger container. Can I use a large trash can (32 gallons)? Do the proportions simply need to be multiplied by 6 to account for the size?

A: Essentially, yes! To work in larger dye vats, you must scale up the amount of each of the vat ingredients to get it to behave similarly on the larger scale. You're leaving the realm of working with kits when you start using containers larger than 10 gallons. Take a peek at the page on my website that goes more in depth on creating your own indigo vat from scratch : Indigo Vat Basics

Dye Vat Capacity

Q: The kit indicates the vat can manage about 5 pounds of items. Can you tell me if that number changes if you are dipping items for longer or more times? So if you dipped 5 pounds of tea towels (for example) 3 times each, would you plan to dye 2 1/2 pounds of tea towels, if you were going to dip them 6 times each?

A: You’ve got it. The darker you dye your items the less total weight the vat can accommodate. Also, the lighter weight your fabric, the less weight the vat can dye. Also, how well you treat your vat contributes to how much material you can push through it. Also, if you tie your pieces up into small bundles so only the surface gets dyed, you can dye more total weight (with the same amount of surface area). The 5lb measurement is really subjective!

Lightweight fabric has more surface area relative to the total weight of the fabric so actually absorbs more indigo per pound than a thick, heavy weight fabric (which has a much smaller surface area). Thin fabrics can be very taxing on a vat, so the yield per weight numbers don’t really apply to to them. The 5lb weight notation on the kit was initially tested using a medium shade of blue, dyed with shibori patterning that was about 50/50 indigo coverage to undyed fabric on medium weight cotton jersey.

Best Way to Dry Indigo Dye

Q: What is the best way to dry indigo dyed fabric? Should I avoid drying it in the sun?

A: Yes, dry in the shade. Indigo is very susceptible to fading when it is exposed to UV light while wet.

Avoiding Sediment in the Ferrous Indigo Vat

Q: How do I protect my goods from the sediment at the bottom of my iron vat. Could you describe in more detail the ideal set-up for a basket or net that I could place in the indigo vat?

A: Yes, the sediment at the bottom of the indigo kit can bond to your piece of fabric and create what I’ll call a ‘false foundation’ upon which all future layers of indigo will bond. When finally washed out, all subsequent layers of indigo will rinse off when the sediment is eventually rinsed off.

If you get your piece into the sediment, make sure to rinse it thoroughly (you can also even use soap, scrubbing sponges or pressure from a hose to blast off the sediment) before dipping it back into the vat to layer on additional color. If the sediment contained a lot of fresh iron, it has the ability to tint your fabric yellowish/brownish where it comes in contact, even after thorough rinsing. To remove this stain, simply add a teaspoon of the citric acid powder included in the kit into a couple gallons of hot water, make sure it is dissolved and soak your pieces overnight (agitating when you remember to). Rinse your pieces until the rinse water comes clear and then resume dyeing.

To avoid all that hassle, you can get some sort of mesh bag (like an inexpensive synthetic mesh laundry sack, or even a layered piece of cheesecloth) and secure it to the rim of the vat and make sure that it only hangs about half way down the vat so that the pieces cannot go all the way to the bottom and make contact with the sediment. You can remove and rinse the bag when you replace the lid on your vat after dyeing.